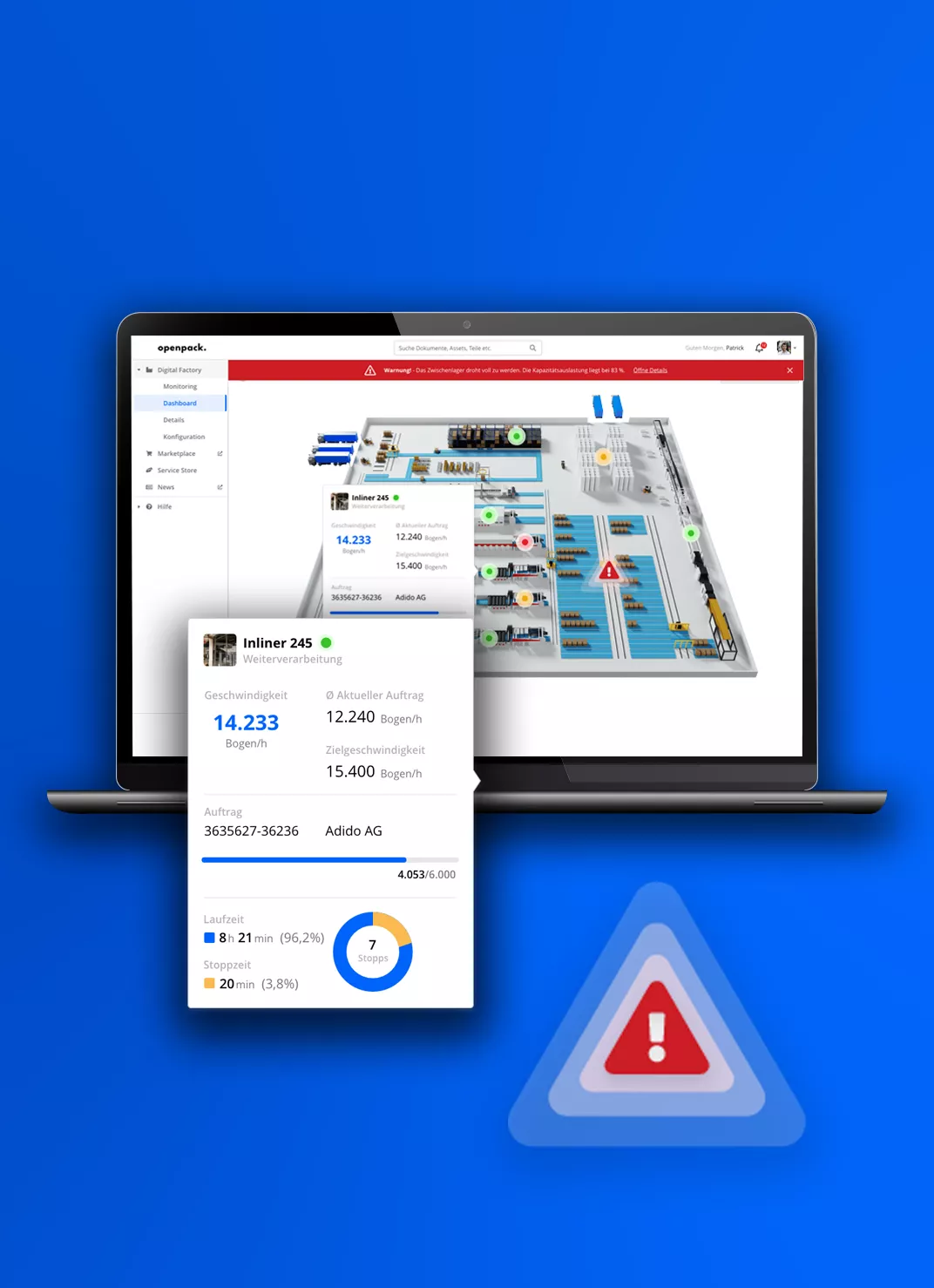

Live comparison of the planned quantity with the actual quantity produced gives you (e.g. production manager and planner) a clear overview of whether the production quantity for the current hour/shift is on target and allows you to take proactive action.

Maintenance staff use Live View, for example, to check the performance of the machines after a repair and to intervene directly if problems / deviations persist.

An overview in Live View and specifically defined conditions reduce response times to machine failures and thus shorten the machine’s downtime, as employees (e.g. production managers, maintenance staff, shift supervisors) are notified of machine downtimes after 10 minutes, for example.

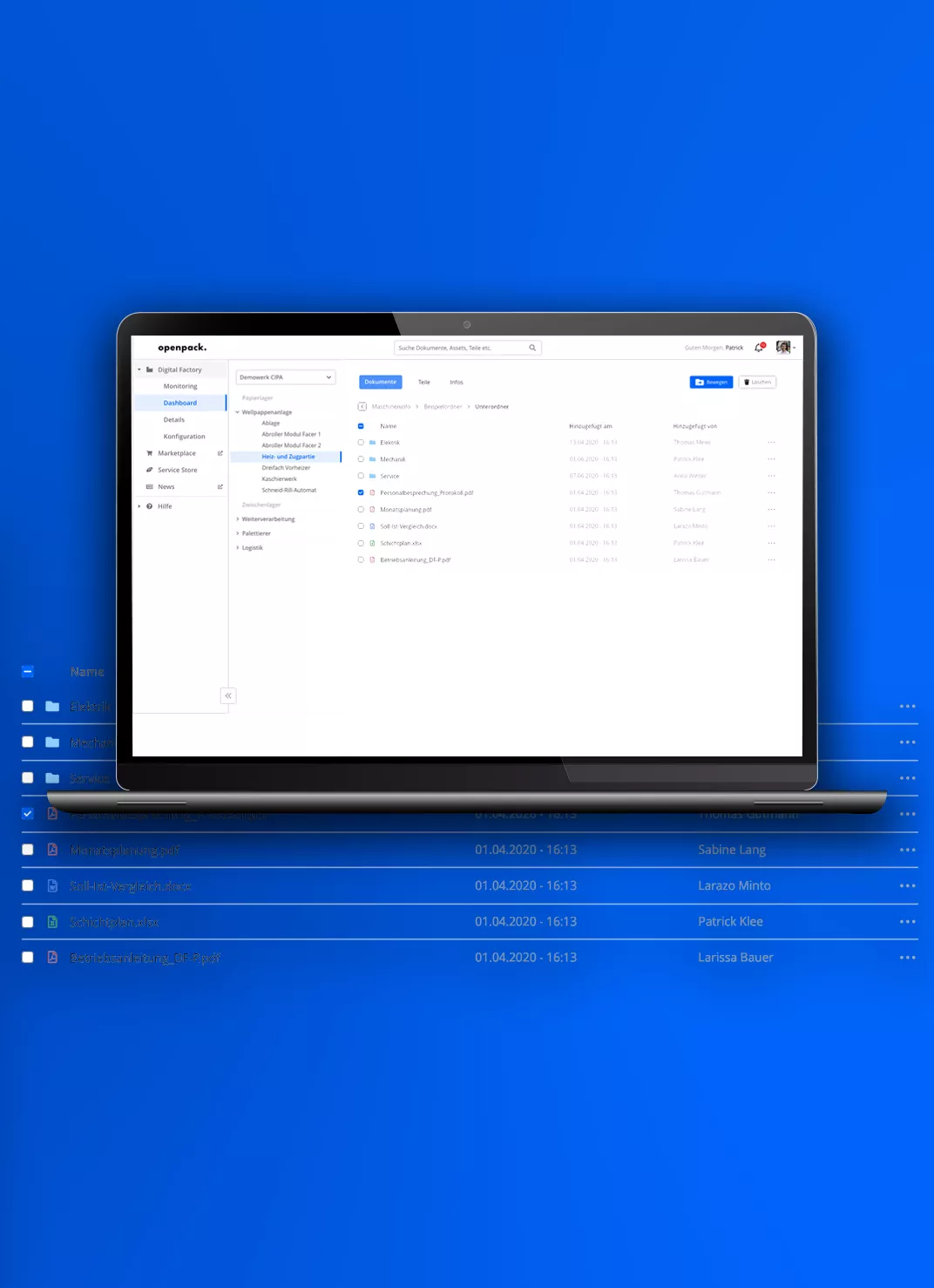

The easily configurable dashboards and the ability to create automated reports with the most important key figures can significantly reduce the manual work involved in preparing production meetings. The effort required to create customised analyses is also reduced.

By displaying and simulating the current and future utilisation of warehouses based on planned orders, bottlenecks in the warehouse can be responded to more quickly. Production managers or planners can also be informed in advance about critical capacity utilisation in the future. Planners use this functionality to keep an eye on the development of the interim warehouse and adjust it if necessary.